ASME QF-482 2013-2025 free printable template

Show details

FORM QF-482 Suggested Format for Fusing Procedure Specifications FPS See QF-201. 3 Section IX ASME Boiler and Pressure Vessel Code Company Name By Fusing Procedure Specification No. Date Revision No. FPS Qualification By testing SFPS If qualified by testing supporting PQR No. s Fusing Process Type Details Joints QF-402 Joint Type Pipe End Preparation Miter Joint Angle Pipe Surface Alignment Sketches production drawings weld symbols or written description should show the general arrangement of...

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign 482 procedure form

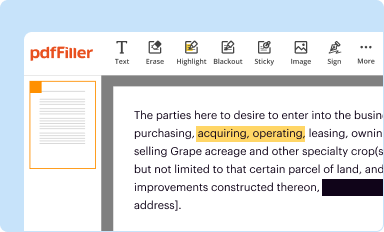

Edit your form 482 specifications form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

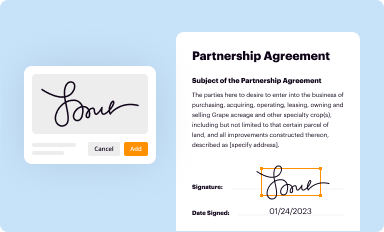

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

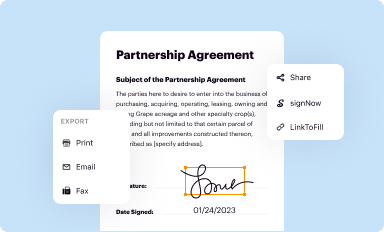

Share your form instantly

Email, fax, or share your form 482 format form via URL. You can also download, print, or export forms to your preferred cloud storage service.

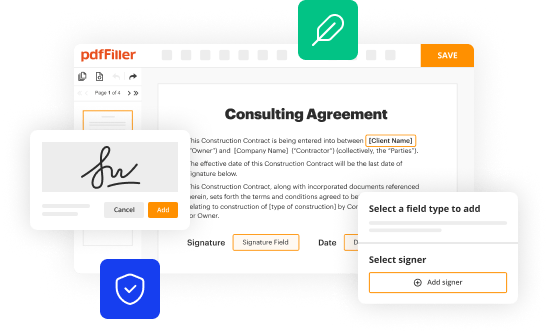

How to edit form 482 procedure online

Follow the steps down below to use a professional PDF editor:

1

Log in to account. Start Free Trial and register a profile if you don't have one yet.

2

Prepare a file. Use the Add New button to start a new project. Then, using your device, upload your file to the system by importing it from internal mail, the cloud, or adding its URL.

3

Edit qf format. Rearrange and rotate pages, add new and changed texts, add new objects, and use other useful tools. When you're done, click Done. You can use the Documents tab to merge, split, lock, or unlock your files.

4

Get your file. When you find your file in the docs list, click on its name and choose how you want to save it. To get the PDF, you can save it, send an email with it, or move it to the cloud.

pdfFiller makes dealing with documents a breeze. Create an account to find out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out asme suggested pdf form

How to fill out ASME QF-482

01

Start by gathering all necessary data pertaining to the project or equipment.

02

Ensure you have access to the latest version of ASME QF-482 form.

03

Begin filling out the identification information at the top of the form, including the name and address of the organization.

04

In Section 1, provide detailed descriptions of the service or application.

05

Complete Section 2 by identifying the specific equipment types and their ratings.

06

Move to Section 3 to indicate the design criteria and code references used.

07

Fill out Section 4 by listing the material specifications and any relevant standards.

08

Review Section 5 for any supplementary information required related to design reviews and inspections.

09

Make sure to sign and date the form, certifying that the information provided is accurate.

10

Submit the completed form to the relevant authority or include it in the project documentation.

Who needs ASME QF-482?

01

Engineers involved in designing pressure vessels and piping systems.

02

Quality assurance and compliance professionals seeking to verify adherence to ASME standards.

03

Manufacturers of equipment requiring ASME certification.

04

Inspectors tasked with evaluating compliance with ASME codes.

05

Organizations involved in the construction or modification of pressure-related systems.

Fill

asme form 482

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I execute qf procedure online?

Completing and signing asme form specifications online is easy with pdfFiller. It enables you to edit original PDF content, highlight, blackout, erase and type text anywhere on a page, legally eSign your form, and much more. Create your free account and manage professional documents on the web.

How can I edit asme suggested download on a smartphone?

The best way to make changes to documents on a mobile device is to use pdfFiller's apps for iOS and Android. You may get them from the Apple Store and Google Play. Learn more about the apps here. To start editing form format fps, you need to install and log in to the app.

How do I complete suggested fusing on an iOS device?

Make sure you get and install the pdfFiller iOS app. Next, open the app and log in or set up an account to use all of the solution's editing tools. If you want to open your 482 procedure pdf, you can upload it from your device or cloud storage, or you can type the document's URL into the box on the right. After you fill in all of the required fields in the document and eSign it, if that is required, you can save or share it with other people.

What is ASME QF-482?

ASME QF-482 is a form developed by the American Society of Mechanical Engineers (ASME) that is used for reporting compliance and data related to the quality assurance of pressure equipment.

Who is required to file ASME QF-482?

Entities involved in the manufacturing, assembly, or testing of pressure vessels and piping systems, especially those seeking certification or adherence to ASME standards, are required to file ASME QF-482.

How to fill out ASME QF-482?

To fill out ASME QF-482, users must provide detailed information regarding the quality assurance processes, materials used, test results, and compliance with ASME standards, typically through a combination of checked boxes and written entries.

What is the purpose of ASME QF-482?

The purpose of ASME QF-482 is to ensure that manufacturers and service providers maintain high standards of quality and safety in the production of pressure-related equipment, thereby safeguarding public health and safety.

What information must be reported on ASME QF-482?

Information that must be reported on ASME QF-482 includes company details, specific equipment or products covered, quality assurance procedures followed, testing results, and any relevant certifications or compliance statements.

Fill out your ASME QF-482 online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Asme 482 Blank is not the form you're looking for?Search for another form here.

Keywords relevant to asme 482

Related to suggested format specifications

If you believe that this page should be taken down, please follow our DMCA take down process

here

.